Llink Technologies Named Phase 1 Winner of U.S. Department of Energy’s Re-X Before Recycling Prize for Industry’s First Automotive Headlamp Remanufacturing Program

- The program remanufactures damaged headlamps to OEM specs, easing supply chain issues and returning valuable chips to the market.

- Program cuts 95% waste per headlamp and extends vehicle lifespans.

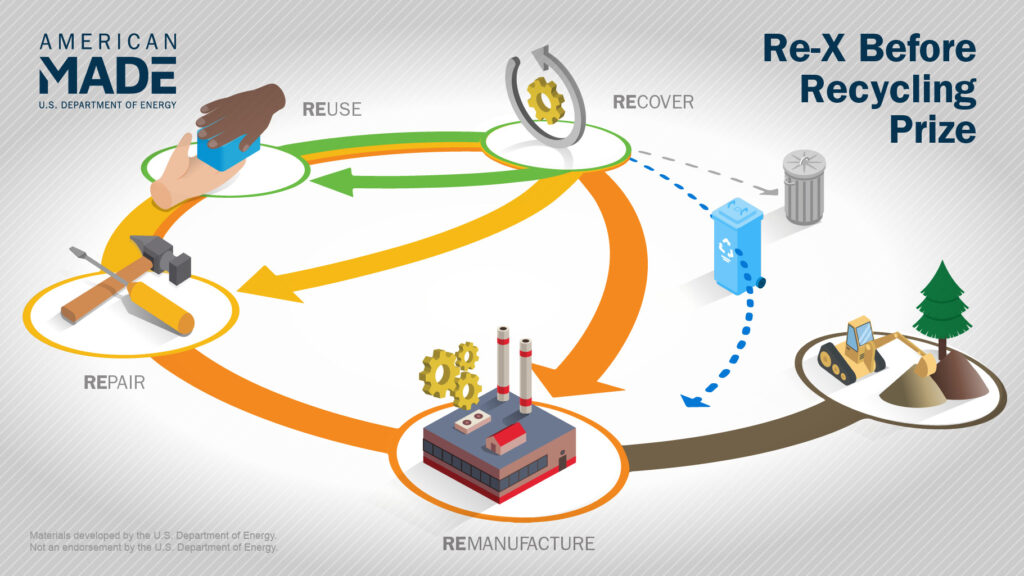

- The DOE’s three-phase competition promotes innovative reuse, repair, and remanufacturing to extend product lifespans.

Brown City, Mich. (December 18, 2024) – Llink Technologies, a Tier-1 supplier and manufacturer of custom automotive interior and exterior products and inventor of the groundbreaking headlamp remanufacturing process, has been named a Phase 1 winner of the Re-X Before Recycling Prize by the U.S. Department of Energy (DOE) for its innovative automotive headlamp remanufacturing program.

The first-of-its kind program currently remanufactures headlamp assemblies for more than a dozen GM branded vehicles. Out of the 20 Phase 1 winners, Llink Technologies is the only automotive supplier and Michigan-based winner of this phase of the competition.

The recognition highlights the program’s ability to deliver significant environmental and economic benefits by extending product lifespans, fostering circularity, and advancing the United States’ transition to a circular economy. Llink is honored to be among the teams representing 13 states to achieve this milestone in Phase 1: Identify.

This three-phase competition launched by the DOE’s Advanced Materials and Manufacturing Technologies Office aims at promoting innovative approaches to extending the useful life of products and components through reusing, repairing, refurbishing, remanufacturing, or repurposing—collectively known as “Re-X.”

Llink Technologies’ headlamp remanufacturing program exemplifies these principles by providing OEMs with a reliable supply of collision replacement parts, addressing capacity and supply chain challenges, and returning valuable chips to the market. The US-patented (US12111366), international patent pending process remanufactures exterior vehicle lighting assemblies to OEM specifications, achieving an impressive 95% waste reduction per headlamp while significantly extending vehicle life cycles. When integrated into an expanded Re-X supply chain, this innovative program has the potential to deliver transformative environmental and economic benefits.

Llink Technologies was awarded $50,000 in cash and $5,000 worth of consultation from National Renewable Energy Laboratory to support the refinement of its program during Phase 2 of the competition.

“As the world’s first remanufacturer of automotive headlamps, we are honored to receive recognition for the environmental and economic benefits of this program,” said Jeff Goulet, CEO of Llink Technologies. “Our team put a significant amount of work into bringing this program to life and we’re proud of the role we play in advancing sustainability practices within the automotive industry.”

Link Technologies is currently in discussions to bring this program to several other OEMs also expand the program globally. To learn more about Llink Technologies’ headlamp remanufacturing program, visit: https://llinktechnologies.com/headlamps/.

The Re-X Before Recycling Prize, which supports this initiative, is funded by the DOE’s Office of Energy Efficiency and Renewable Energy’s Advanced Materials and Manufacturing Technologies Office and administered by the National Renewable Energy Laboratory. For more information about this prize, visit: https://www.energy.gov/eere/ammto/re-x-recycling-prize.